Manufacturing Process

PP Woven Sacks are generally manufactured and printed as per the Customers’ demands/needs. The end users adopt different kinds of Colour Combinations and Designs in the Printing of these Sacks to convey the massage(s), characteristic(s), quantity & quality related details and handling instructions etc. For some kind of specific applications like filling of Hydroscopic Materials e.g. Chemicals, Fertilizers, Food Products etc. these Woven Sacks are laminated also.

PP Woven Sacks are generally manufactured and printed as per the Customers’ demands/needs. The end users adopt different kinds of Colour Combinations and Designs in the Printing of these Sacks to convey the massage(s), characteristic(s), quantity & quality related details and handling instructions etc. For some kind of specific applications like filling of Hydroscopic Materials e.g. Chemicals, Fertilizers, Food Products etc. these Woven Sacks are laminated also.

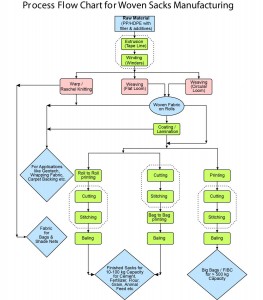

The Process of manufacturing PP Woven Sacks involves following four steps:

- Tape plant

- Extrusion

- Weaving

- Finishing & Stitching

Tape plant

Extrusion Tape Stretching Plant have been developed for producing PP / HDPE tapes for many applications such as Woven Sacks / Knitted Bags / Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications…

Extrusion/ lamination

The process of manufacturing PP woven bags involves mixing raw materials starting with PP pellets and other additives, extruding the raw materials into a yarn PP resin is heated with feeler of CaCo3 and pigment, melted and extruded as a flat film. It is then slit into tape yarn by the slitting unit and stretched and annealed. Next, a take-up winder winds the heat oriented tape yarn onto a bobbin.

The Raw Material (PP & Filler) in the Granules form is fed to a Raffia Tape Manufacturing Plant to obtain the Raffia Tapes of PP. The Raw Material Mix is prepared in a Tray adjacent to the Feed Hopper. The prepared Mix is sucked in to the Hopper by Vacuum. The Raw Material Mix is fetched to the Extruder of the Plant; where the same is melt by applying controlled External Heat on the Barrel. The Molten Mass is forced out through a Die Head into a Cooling Tank, in the form of Sheet/Film. The cooled & solidified Sheet/Film is passed through the Knifes to obtain Raffia Tapes of higher Denier (a Unit by which the fineness of a Yarn is measured). High Density Polyethylene(HDPE) or Polypropylene(PP) granules are first converted in to 2.5 mm wide tapes by Extrusion process. The Raffia Tapes received from the Plant are stretched and annealed. These are then wound on Cheese Pipes with the help of the Sets of Winders.

Weaving

weaving the yarn into a fabric in a process similar to the weaving of textiles . These flat tapes are then woven into circular fabric by Circular weaving machine. Thus woven circular fabric is then cut in to required dimension . Thread from the bobbin in the circular loom’s creel stand is woven into tubular cloth The Weaving of Raffia Tapes into Cloths is carried out in Circular Looms, which produce Circular Cloth of desired Width. The process of Weaving is Automatic and Continuous in nature. Numbers of Circular Looms are installed so as to match the Effective Output of the Raffia Tape manufacturing Plant. The Cloth produced by each Loom is continuously wound on Rotating Pipes.

Finishing & Stitching

The Rolls of Woven Cloth are carried out to the Finishing & Stitching Section of the Unit. The Cloth is cut into desired size and the printed. After printing the cut pieces are sent for stitching. Prior to the stitching of the Cloth, a valve is made in one corner of the cut piece, as per the Customers specification. The Woven Sacks passed through the Quality Control Test are bundled in 500 or 1000 Nos. and pressed on a Bailing Press. The pressed Woven Sacks are wrapped, bundled, packed and dispatched.

The Quality Control checks are carried out at each and every step to avoid rejections. The parameters pertaining to the Weight, Denier, Bursting Strength etc. are strictly adhered to.